Why Welding is Vital to Manufacturing

More Than Half of All Products Made in the U.S.A. Requires Welding.

Unveiling the Power of Welding

Welding is an essential part of the manufacturing process in the United States, and it's more important than you might think. In fact, more than half of all products made in the U.S.A. require some form of welding. From the simplest everyday items to the most complex machinery, welding plays a crucial role in the creation of nearly everything we use.

Let’s dive into why welding is so fundamental to U.S. manufacturing, the industries that rely on it, and the role it plays in our economy.

The Backbone of Manufacturing

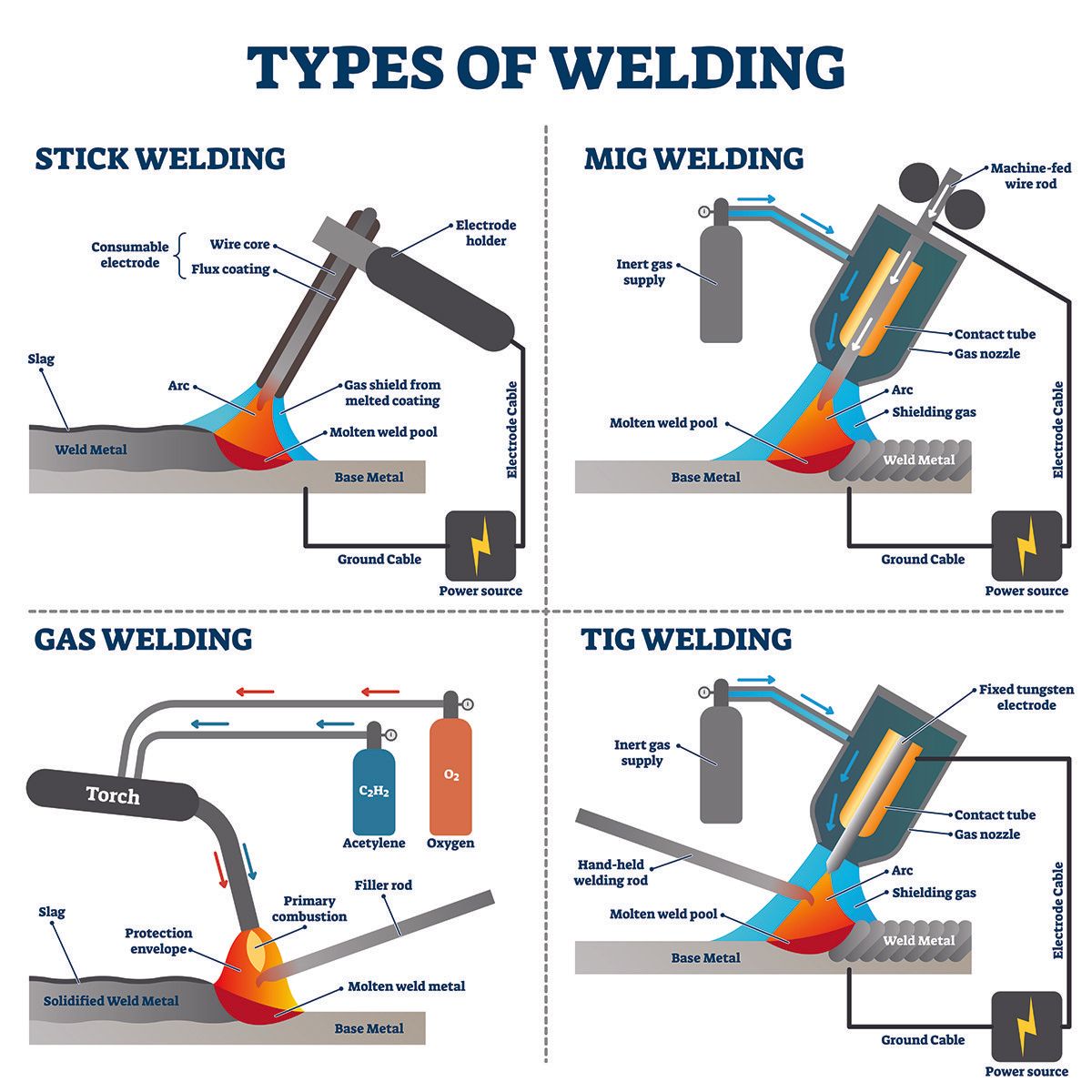

Welding is the process of joining materials, usually metals or thermoplastics, using heat, pressure, or both. It’s a critical skill in creating durable and high-quality products. Whether it’s an automobile, a bridge, or even a kitchen appliance, welding is often the key to holding everything together.

According to the American Welding Society (AWS), over 50% of all manufactured products in the U.S.A. involve welding in some way. This includes everything from aerospace components, medical devices, and heavy machinery to consumer electronics and home appliances. In fact, welding is used in nearly every manufacturing sector. Without it, we would be unable to produce the strong, reliable products we depend on daily.

Welding in Key Industries

- Automotive Industry

The automotive sector is one of the largest users of welding technology. The manufacturing of cars, trucks, and other vehicles involves hundreds, if not thousands, of welded joints. Welded parts are critical for the structural integrity and safety of vehicles. The process ensures that vehicle frames, exhaust systems, and engine components are firmly bonded and able to withstand high levels of stress and pressure. - Construction and Infrastructure

Welding plays a crucial role in the construction of bridges, buildings, and other infrastructures. Steel beams and supports that form the foundation of skyscrapers and highways rely on welding to remain stable and safe. Without welding, it would be nearly impossible to assemble large, heavy steel structures with the level of precision and durability required. - Energy Sector

The energy industry is another major sector that relies heavily on welding. From oil rigs and pipelines to power plants and renewable energy systems, welded components are at the heart of nearly all energy infrastructure. Whether it’s ensuring the safety of an offshore drilling platform or the efficiency of a wind turbine, welding provides the strength and reliability needed for critical energy systems. - Aerospace and Defense

The aerospace industry relies on welding for assembling aircraft, spacecraft, and military defense systems. The high-performance materials used in this sector, such as titanium and specialized alloys, require precise welding techniques. Welding is also critical for the assembly of rocket engines, aircraft fuselages, and other highly engineered systems that must endure extreme conditions. - Consumer Goods and Appliances

On a smaller scale, welding is just as important in the manufacturing of household items like refrigerators, dishwashers, and even smaller items like metal furniture. The components of these appliances are often welded together for added strength and to ensure that they function safely and effectively for years.

Why Welding Matters

- Strength and Durability

Welding creates strong, permanent bonds that can withstand extreme conditions. This strength is why welded joints are so commonly used in heavy machinery, infrastructure, and vehicles that are subjected to stress and wear over time. Without welding, the integrity of these products would be compromised. - Precision and Quality Control

Welding allows for precision in joining materials, ensuring that products meet exact specifications. Whether it's a complex aerospace part or a simple metal shelf, welded components are made to fit perfectly and perform as intended. Advanced welding techniques, such as robotic welding, further ensure that each joint is made with high consistency. - Versatility

Welding can be used to join almost any type of metal and in a wide variety of applications. From aluminum to stainless steel, the adaptability of welding makes it a go-to process for manufacturers across industries. This versatility is crucial in meeting the ever-growing demands for innovation in manufacturing. - Cost-Effectiveness

Compared to other methods of joining materials, welding is often more cost-effective. It requires fewer materials and less labor than methods like bolting or riveting. For manufacturers, this translates to reduced costs and increased productivity, which is especially important in a competitive global market.

Welding’s Impact on the U.S. Economy

Welding isn’t just a technical skill; it’s a driver of the U.S. economy. According to the AWS, the welding industry contributes over $300 billion to the U.S. economy annually. This includes the value of welded products, labor costs, and the industries that depend on welding to thrive.

Furthermore, welding is a highly skilled trade that supports millions of jobs across the country. Welding professionals are needed to meet the growing demand for quality manufacturing, ensuring that products are made safely and efficiently. As industries continue to evolve and grow, the demand for skilled welders will only increase, which is great news for both the economy and individuals looking to pursue a rewarding career in welding.

Looking to the Future

As manufacturing technology advances, welding techniques are evolving too. New technologies like laser welding, robotic welding, and 3D metal printing are pushing the boundaries of what’s possible in fabrication. These innovations are helping manufacturers produce even more precise and complex products while continuing to keep costs manageable.

Welding also plays a role in sustainability, with the ability to repair and reuse materials, reducing waste. As industries move toward more sustainable practices, welding will undoubtedly remain an essential tool in helping reduce the environmental impact of manufacturing.

Conclusion

From the cars we drive to the buildings we live and work in, welding is everywhere. More than half of all products made in the U.S.A. rely on welding at some stage of their manufacturing process, demonstrating the undeniable importance of this craft to our daily lives and economy.

At its core, welding isn’t just about joining metal; it’s about creating the infrastructure, vehicles, and products that power our modern world. As technology continues to advance, welding will remain at the forefront of innovation, ensuring that we can continue to build stronger, more durable, and more efficient products for generations to come.

Are you in the metal fabrication industry or looking to explore welding as a career? It’s a field that’s critical, rewarding, and full of opportunities.

4145 Billy Mitchell Dr, Addison, TX 75001

All Rights Reserved Holly Fabrication | Created + Managed by ⬜️ N U A N C E Collaborative