Common Welding Methods

February 18, 2020

The use of welding can be traced over several millennia, examples of welding can be found coming from the Bronze and Iron ages in Europe and the Middle East. Since those ancient times welding and

its techniques and applications have evolved greatly, the tools, chemicals, and equipment now used today allow for precision welding as you will find in our HollyFab fabrication shop.

Call Us

Welding Methods at HollyFab

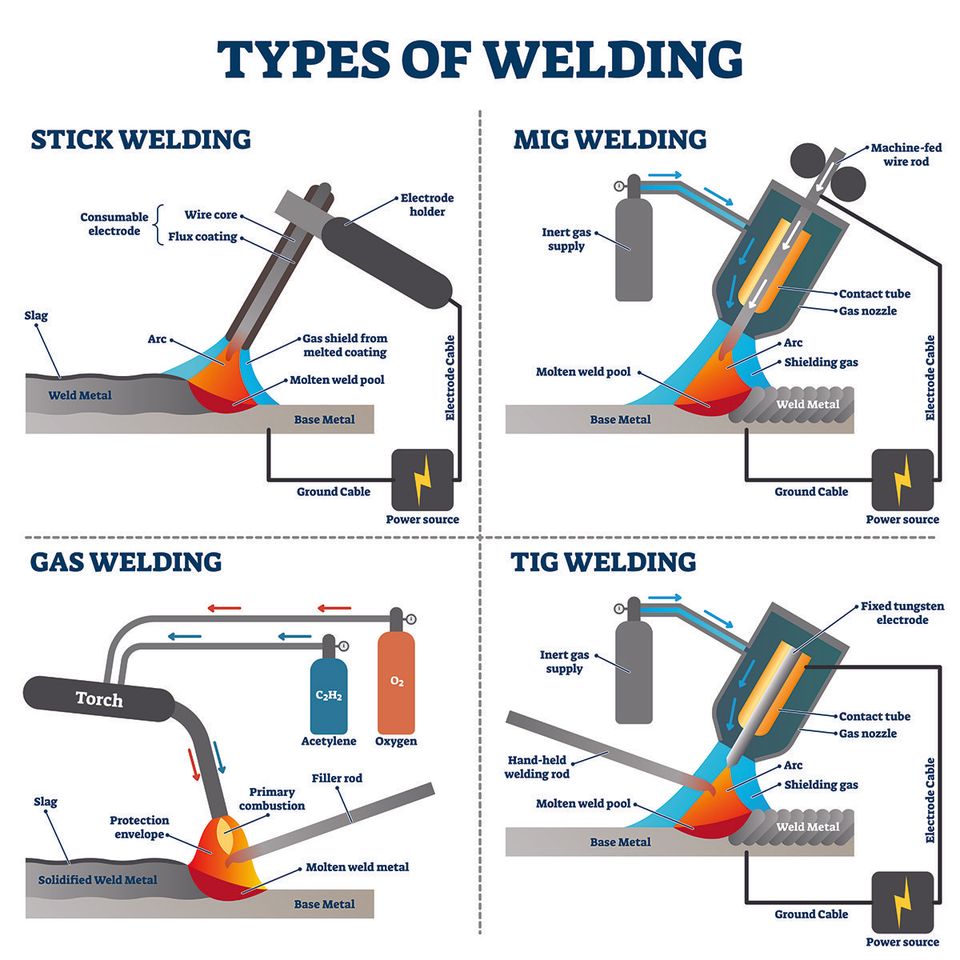

MIG

‘metal, inert gas’

(GMAW) also commonly named ‘Gas Metal Arc Welding’

Mig welding can be used to achieve great results with typically aluminum and steel and it’s the most generally used welding technique for industrial purposes, it uses a continuous consumable electrode and a shielding gas.

TIG

‘tungsten, inert gas’

(GTAW) also commonly named ‘Gas Tungsten Arc Welding’

Tig welding produces an extremely high-quality weld and is mostly used to weld thinner or more intricate sections of stainless steel and non-ferrous metals such as aluminum and copper. This type of welding whilst toughest to master produces welds that are extremely resistant to future corrosion and cracking.

STICK

(SMAW) also commonly named ‘Shielded Metal Arc Welding’

Stick welding is a very adaptable method and is a popular method or repair and to weld iron and heavy steel structures and stainless steel. It also lends itself well to most other alloys such as nickel, copper, and aluminum.

Oxy-acetylene

Also commonly named ‘Oxy Welding’ or ‘Gas Welding’

Using a neutral flame, oxy-acetylene welding is primarily used for the cutting and joining of non-ferrous and ferrous metals with the exception of brass. It’s uses are very versatile, and it’s regularly used to anneal metals prior to bending and forming.

If you have a welding project or questions about any metal fabrication methods we use at HollyFab, give us a call we’d be glad to help.

Hours of Operation:

Mon - Thu 8:00 am - 5:00 pm

Friday - 8:00 am - 3:00 pm

Sat - Sun Closed

4145 Billy Mitchell Dr, Addison, TX 75001

© 2025

All Rights Reserved Holly Fabrication | Created + Managed by ⬜️ N U A N C E Collaborative